ok so here we go.....

Making jewelry by hand -also called construction.

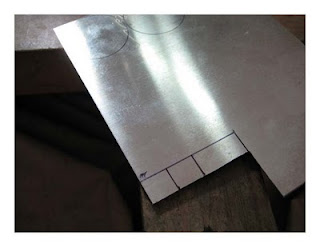

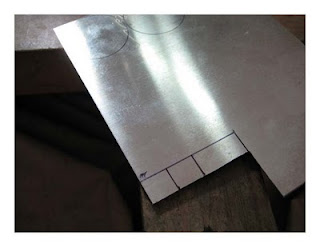

As you can see I have a rather large sheet of silver,

and I want to make a rectangular box of sorts.

So I measure and mark my two outside walls

and then cut them out with my jewelers saw.

I use a very small blade, that way

when my cut line is not straight (which it never is)

I don't have that much to file down.

This is what we are making,

or attempting to make.

Original artwork done by Popartmonkey.

This is a commission piece,

which normally I don't do, but I like his work

and I'm very proud of him for quitting smoking.

On the back of the piece I will stamp his 'quit' date.

Time to cut apart what will be the outside walls.

I was taught to cut on the outside of the line,

but I try very hard to keep them as even as possible.

My brain is wired to cut outside the line.

My last boss could not understand this.

He'd say 'Cut on the line.'

I'd say 'Not gonna happen.'

What was one, now is two.

Whats all that junk on them?

Well like saw dust, that's silver dust.

See the tan thing below?

That's my bench skin which catches all the dust

and whatever else I might drop by accident.

Yes its a skin of some type of animal,

smooth side turned up so the dust won't get stuck.

I scoop up this dust and keep it in a plastic bag

in a coffee tin and when it gets heavy and I get poor,

I turn in my 'scrap' for a credit from my supplier.

This is what recycling silver means.

If you think buying from an eco-friendly jeweler

unless they are making things out of hemp,

you my friend are getting taken.

Silver is mined as is gold and copper.

So whether you got it first or recycled

it doesn't matter the deed has been done.

As I mentioned before I can't cut a straight line

so we file.....

Each side needs to be straight because later on

this will be VERY important.

I'm doing this in my lap which is my own technique

so I can get the most pressure on metal.

Its important to switch around the piece

so you don't end up filing some weird angle.

Oh yea. Been there done that.

Time to cut out the short ends

of my rectangle.

Oh No! They are too small!

I didn't add the thickness of the walls

to my measurements. Grrrrr!

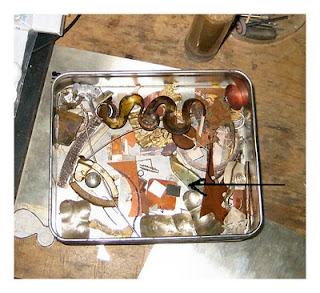

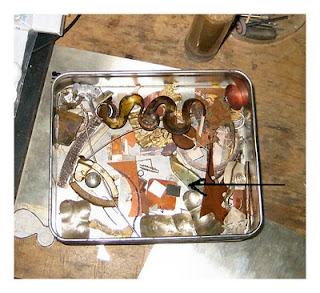

This is where my too small pieces go

(see the arrow?)

Its my scrap box which can at times be very exciting.

But not today,

because I don't see any pre-made boxes in there.

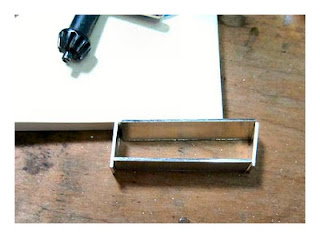

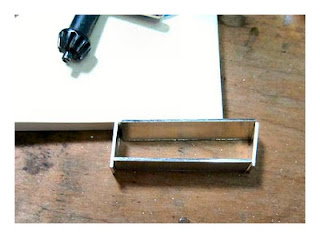

So I go back and draw larger sides,

cut, file and hello outside form!

It still needs to be soldered but

that's another lesson for another day.

I still need to make an inside frame,

because the black line on his drawing

is included in this design.

So I need to make a space for it.

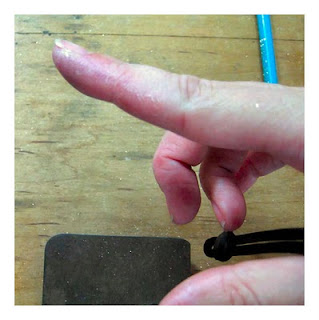

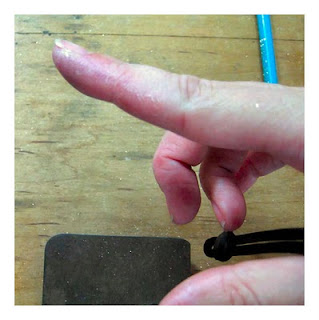

This is my poor finger.

Looks better now.

Don't expect to keep up a manicure

if your working with metals.

I swear my finger was aching,

so this is as far as we got today.

I'm expecting to rerun this scenario

to make the inner forms.

I won't bore you with that but

I'll keep posting my progress so you can see

what goes into making this piece by hand.

Follow my blog with bloglovin